Want to Improve the Environment?

Bokashi Ferment!

All urban and agricultural centers need to find effective ways of handling the mountains of waste they produce on a daily basis.

Landfills can no longer be used efficiently because they are costly, polluting and difficult to manage.

Agricultural centers have to contend with large amounts of animal waste and manure. This is a hard to manage problem.

Many people are concerned about gases produced in composting waste and about methane produced in and around manure collections. Nitrate and phosphate run-off foul waterways and kill fish and harm aquatic life.

Although manure has for many years been frequently used in agriculture to enrich the soil, it is now recognized that the practive of spreading manure over the land surface previously accepted is risky and contributes to phosphate and nitrogen fouling of waterways.

A less appreciated risk related to improperly treated manure and pet waste is the spread of coliforms and pathogens that can harm and contaminate wells, lakes and streams.

An efficient environmentally friendly solution is needed to treat waste.

Fortunately, there is a very efficient and effective way of treating all forms of green waste using naturally derived micro flora and fungi.

Bokashi fermenting waste resolves most of the problems linked to waste processing.

It’s easy to implement. It requires little effort and can be done anywhere.

What is Green Waste Anyway?

We live on a thin crust of soil, rocks and dirt. Be thankful that microbes, fungi, plants, and all living creatures inhabiting the earth have evolved to decompose and return that which was borrowed during life to cycle forward sustaining life in its many and varied forms.

Nothing is ever wasted. Our planet is beautifully colored. It is constantly changing through the seasons and over time. Those colors seen so vividly from space are signs of life and the plants with their varied shades of green signal immediately the planet is alive.

We look at decomposing matter or debris that will decompose as waste. In reality it is just a part of the life spectrum. Plants, bacteria, fungi, or living cellular organisms that will eventually decay or decompose define what we call green waste.

I look at decaying and decomposing debris as a treasure supporting and maintaining life in all the varied forms.

Nature recycles.

Some Key Environmental Issues to Resolve:

Green waste should be recycled. Decaying and decomposing green waste can cause problems if it is done improperly or carelessly. Here are issues that we want to consider whenever recycling waste.

- Air Quality

- Water conservation

- Water quality – minimizing phosphate and nitrogen run-off

- Water quality – eliminating coliform and pathogen pollution

- Heat generation and contributions to potential global warming

- Minimizing demand for petrol fertilizers

- Reducing Transport Traffic, trucking long hauling to processing centers

- Minimizing pest pressure without dependence on pesticides and fungicides

- Efficient use of lands minimizing waste.

- Soil fertility – methods of improving and supporting biologically active soils minimizing or eliminating the need to add phosphates and nitrates

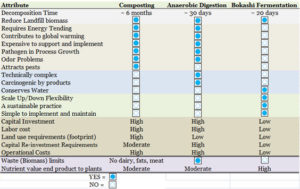

I am going to show you with comparative attributes to competing technologies that bokashi fermenting waste is easier, less costly, much more efficient, and in a commercial facility far more profitable, underscoring the environmental benefits to bokashi (acidic anaerobic) fermenting green waste. There are many benefits.

US environmental agencies have had little experience with Bokashi fermenting:

Research and experience has shown that bokashi fermenting in small scale operations very efficiently and cost effectively eliminates serious environmental problems that are linked to other competing technologies. It is important to proceed on an industrial scale, documenting that the same beneficial attributes related to bokasi fermenting on a small scale are observed as more and more waste is processed in this manner.

Glossary of Useful Terms:

I will refer to a few useful terms which are simply defined.

Organic matter – refers to any material derived from plant material and has generally high amounts of carbon, hydrogen, nitrogen and lesser amounts of sulfur. Since animals live off of plants they are part of the organic matter on the planet.

Note: all animals, insects, sea creatures, microbes, fungi and viruses including those feeding on other creatures derive from and depend on plant material (algae and seaweed are plant material).

Green waste – any organic matter.

Feed stock – refers to the type of green waste being processed or fermented. Food waste, manure, marijuana waste, yard waste are all examples of waste recycled in various forms.

Acidic – a measure of acid conditions normally expressed in terms of hydrogen ion concentration. Acidic is in the range below pH 7 to 0 (most acid content), and above pH 7 is neutral and then alkaline.

Anaerobic – means conditions where oxygen is eliminated or excluded.

Fermentation – is a process that involves typically micro organisms that are capable of breaking down and altering food or green (plant derived) materials, examples being yogurt, cheese, beer, or wine production.

Bokashi – a Japanese term that translates as “fermented” organic material. Kim chi, soy sauce, wines are products that are made by fermenting. The manner in how material is broken down or fermented is dependent on the kinds of microbes and conditions used.

Acidic Anaerobic fermentation – is the technical scientific term that involves Bokashi fermenting as it is done with specialized microbes where oxygen is excluded. The microbes secrete enzymes which break down complex molecules in the organic matter resulting in many metabolites.

Enzymes – complex molecules that have evolved to cleave or disrupt various chemical bonds in larger molecules very quickly and efficiently. Enzymes are the tools microbes use to obtain energy and materials to create other complex molecules.

Metabolites – when large molecules are broken apart into smaller and smaller building blocks, metabolites are formed. These are the many and complex pieces that are formed as the larger molecules are “digested” by enzymes.

Struvite – a naturally forming mineral that precipitates (forms stones) in soil when magnesium, phosphate and ammonia are present.

Struvite acts as a time release material allowing both phosphorous and nitrogen to feed plants on a continuous basis because it is only slightly soluble in water.

Struvite locks phosphate and nitrogen in the soil preventing harmful run-off into waterways, wells, and lakes. Struvite will not form with nitrates, the common form of nitrogen fertilizer and will not form unless magnesium, phosphate and ammonia are all present at the same time.

Comparative Attributes – Bokashi vs Competing Methods:

One solution in processing green waste involves composting. Another solution is to digest the waste in a methane producing plant (AD technologies). Composting takes a long time, requires a lot of effort and equipment, is not particularly efficient, and ties up land that could be used more efficiently in other ways. AD methane producing processing plants are very expensive and hard to manage and ultimately toxic in the environment.

A third alternative, Bokashi (acidic anaerobic) fermentation is the simplest, least costly, and fastest way of recycling organic waste. It is an anaerobic process with specialized microbes and requires only 10 days to reach its end point. The bio-pulp obtained has a high market value.

Unlike the composting process and AD technologies which contribute significantly to greenhouse gas production, Bokashi fermenting eliminates greenhouse gases related to green waste recycling. Carbon is not oxidized as occurs in composting and virtually all of the carbon returns to the soil where it is sequestered.

Bokashi fermenting

- can be done all throughout the year,

- is very scalable,

- produces neither heat nor gases,

- and eliminates nuisance factors like odors and vermin linked to composting sites.

Most importantly, this technology can dramatically reduce the community’s dependence on petrol derived (fertilizing) products. The fermented bio-pulp when mixed with soil establishes healthy high organic content soil free of pathogens and no additional fertilizers are required.

Farm lands can thus be greatly improved and run more efficiently by cycling the bio-pulp through the soil. When waste is processed and recycled to the land, true sustainable agricultural practices are easily achieved.

This cycling process conserves water too and the nutrients produced by bokashi fermenting are avidly fixed in the soil reducing ground water nutrient leaching which has been a difficult problem to resolve in the farming communities.

Table 1: Attribute Comparison for Composting Anaerobic Digestion and Bokashi Fermentation

It is important to more carefully examine the attributes related to methods used to recycle organic waste. Bokashi fermenting is by far the superior least toxic and most cost effective way to solve the organic waste problem.

Curbside diversion programs using bokashi fermenting in a residential setting are easy to implement. The home owner takes responsibility to process all organic waste. No waste ever gets to the curbside. Cities no longer have a need to pick up the green waste saving labor and fuel and time.

Cities adopting a bokashi fermenting plant can process industrial/commercial green waste easily in a small space and no longer have to ship the waste to a facility where much of the material will be oxidized in a composting operation.

Green waste should be processed locally where it is produced. Recycling the fermented end product (bio-pulp) to the surrounding gardens, farms and parks is a positive welcome benefit. The soil organic content, so badly depleted over years of neglect can easily be restored in this process resulting in a truly sustainable soil enrichment.

Conserving water, cleaning up the soil, and reducing greenhouse gases is a cost efficient process. It takes little effort and time and it makes a lot of sense. Bokashi fermenting is the only one of the 3 recycling options that is easy to implement, costs little to put in place, cleans up the air and water and restores soil needed to grow products we consume free of chemicals and toxins.

Fermenting – Environmental Observations & Benefits:

Recycling green waste is best done by fermenting. This is technically and scientifically called acidic anaerobic (Bokashi) fermenting the waste.

A great amount of research is on going and already important observations have been documented.

Air Quality Statement:

Green waste placed in a fermenting unit never touches the ground so pathogens can not contaminate the ground in the area where recycling is done. Oxygen is excluded during the approximately 2 weeks waste is in process and waste is broken down into metabolites. Pathogens are eliminated. The soil derived microbes, flora and fungi involved in a Bokashi Cycle Operation are proprietary. They are all derived from native soils.

No chemical additives or toxic materials are included in the bokashi culture mix used to ferment green waste. We’ve patented the industrial scale commercial process and now have quality control standards in place so growers can rely on a consistent high standard end product. We want all growers to know that the fermenting process is standardized and that products in the field are reliably useful.

Experience has shown that the weight of material entering the fermenter is virtually identical to the weight of material at the end of the fermenting cycle. Water is conserved. Very little carbon escapes in the form of carbon dioxide.

Unlike composting where oxidation and heat and the escape of many gases into the atmosphere occurs, bokashi fermenting conserves mass and eliminates greenhouse gas production. Compost piles shrink down as oxidation takes place.

Bokashi fermenting units retain their mass as waste is metabolized and no material is lost in this process.

Carboxylic acids are produced as the waste is metabolized. These acids as they form inhibit completely the organisms that would produce methane. They are also involved in forming other important molecules that help plants obtain nutrients and they feed organisms living in the soil. No methane is formed in this process.

We know of no other competing technology that converts green waste to a useful product minimizing so efficiently greenhouse gas production.

Nitrogen is trapped as the ammonium ion and does not escape into the atmosphere as ammonia because carboxylic acids form trapping ammonia as the non-volatile ammonium ion as material is metabolized.

Water conservation:

Because no heat is produced in this process, and the water released with cellular disruption remains in the fermenting bin, water is retained and conserved. Some additional water forms with fermenting too.

No water is lost in this process. Water is both conserved and manufactured in this process. No other green waste recycling competing technology does this.

It has also been shown that an expanded diverse population of flora and nutrients supporting the soil food web form when the end products are mixed into soil. The bokashi formed bio pulp (fermented end product) can be mixed into soil to produce a fertile rich media to support plants. It can also be separated into both a tea and a cake for easier handling. Adding the fermented end product to soil results in a biologically activated soil.

The biologically activated soil greatly increases the soil’s avidity for water because in part the many living organisms have water trapped within the cellular compartments buffering the flow through and loss of water in the soil. They hold onto water while alive, and release water to other organisms and plants when they die.

Because cell turnover and the sharing of nutrients between micro flora and plants is ongoing, this results in less water demand to maintain healthy plants. The impact is currently estimated at reducing water requirements by at least 20% in arid environments when used in farming applications.

Water quality – minimizing phosphate and nitrogen run-off:

Bokashi fermenting waste minimizes nutrient run-off into waterways.

There are many contributing factors that lead to a dramatic reduction in both nitrogen and phosphate run-off into waterways.

Unlike composting where most of the nitrogen is in the form of nitrate (negatively charged ions), nitrogen ends up at virtually 100% ammonium ion (positively charged ions) when waste is bokashi fermented. Bokashi fermenting is a reducing environment so nitrates get converted to ammonia. Ammonia is trapped as the ammonium ion by carboxylic acids that are also forming as waste is metabolized.

Negative ions (nitrates and phosphates) are repelled by clay particles and rapidly move with water. That is why phosphates and nitrates in fertilizers are always moving into lakes and streams away from plants and never stay fixed in soil unless they are organically bound up or precipitated in mineral forms.

Clay particles in the soil are negatively charged. Ammonium ions are electrostatically tightly bonded to clay particles minimizing nitrogen run-off.

Both phosphate and ammonium ions in the presence of magnesium naturally precipitate to form a very insoluble mineral called Struvite (see glossary of terms).

Struvite is a problem for companies that have to maintain pipes and valves as it naturally precipitates in water pipes and around valves blocking and destroying their efficient operation. It costs water departments thousands of dollars to keep pipes and valves free of natural precipitating struvite. Both nitrogen and phosphorous are essential for healthy plants. This mineral that is a problem for people who maintain pipes is a great way to slowly release both nitrogen and phosphate in the field to help sustain healthy plants.

In agriculture it is a huge advantage to have struvite in the soil because it holds both the nitrogen and phosphate as a mineral deposit where it formed in the soil near plants and it does not rapidly leach away to contaminate waterways.

Both the plants and the expanded diverse microbes, fungi and flora living in the soil are competing for nitrogen and phosphate needed for proper cellular activity so in this form with its slow delivery back to the soil it reduces the demand for petrol derived fertilizers and additional phosphates while working against leaching into the waterways.

Most growers find in short time they no longer need to supplement soil by heavy loading with nitrogen based fertilizers and phosphates which always rapidly move with water and account for much of the current problem in managing formally clean waterways.

Water quality – eliminating coliform and pathogen pollution:

There are many documents and studies showing that bokashi fermenting is highly lethal to most pathogens including coliforms.

This killing effect is so efficient that colonies are frequently obliterated in 48 to 72 hours. It is thought to be due in part to naturally forming antibiotics produced by fungi competing with non pathogenic bacteria and partly due to free radical nitrites formed transiently as nitrates reduce to ammonium forms, and certainly in part due to the extreme environmental changes (sharp reduction in pH and exclusion of oxygen) where pathogens can’t easily survive.

Studies done by the FDA and USDA have also shown that the combination of trace amounts of butyric acid at low pH levels are particularly lethal to E. coli and coliforms contaminating meat products.

Butyric acid is always formed in trace amounts in this fermenting process and the pH is always ending at the acidic end of the spectrum assuring that the same pathogen killing conditions are established when green waste is fermented.

No Heat generation – eliminates potential global warming Contribution:

Bokashi fermenting generates no significant heat during its entire process from beginning to end and normally takes place at ambient temperature. Lower temperatures slow the process and higher temperatures increase the rate of enzymatic activity. There is no heat contribution to this process effecting the environment. This is quite the opposite from other competing technologies which either require heat or generate heat as material is broken down. Compost piles generate a lot of heat and almost 50% of composted waste escapes into the atmosphere as greenhouse gases. A lot of water is also lost in composting waste.

Minimizing demand for petrol fertilizers:

In addition to the many flora, fungi, and microbes involved in this process and the variety of metabolites forming, complex molecular structures that are highly beneficial for plants form. Humic and folic acids, cytokines, auxins, gibberellins and most likely a number of other useful growth hormones that positively benefit plants form in the fermenting environment.

There are many nitrogen fixing organisms involved in this process. Their number and diversity clearly expand as waste is metabolized. Experiments in soil monitoring show both available nitrogen and phosphate are well maintained and even restored after heavy rains trigger transient drops in their level.

Within a matter of hours the tested nitrogen levels rise suggesting that nitrogen fixing activity is in part accounting for stabilization of the biologically active soil.

Growers have consistently reported higher yields and healthier plants using the end products obtained by fermenting green waste and some of them have stopped using supplemental chemical fertilizers.

Reducing Transport Traffic, trucking, long hauling to processing centers:

Bokashi fermenting green waste requires no windrow use and frees up the land for other uses.

Because it takes a small foot print to process a large volume of waste and produces no notable foul odors near an operating plant, waste recycling can be done close in where waste is produced and near urban centers without complaints. This means processing centers can be reduced in size and dispersed and no longer need to be built on a massive scale far from the community where waste is produced.

By decentralizing process centers and establishing recycling facilities close in where waste is produced, long haul transport and trucking is reduced significantly. Because no diesel fuel is required for windrow machinery, turning waste, or mixing waste and trucking is minimal and fuel savings are substantial.

This is also a benefit to improve air quality by eliminating diesel use requirements.

Minimizing pest pressure without dependence on pesticides and fungicides:

Growers using green waste fermented and recycled products report consistently a great reduction in pest pressure.

This may be in part to healthier plants more able to resist opportunistic infections and attacks by pests. It is also likely due to the filling of viable habitat with symbiotic beneficial organisms thus excluding habitat for pests and opportunistic organisms that feed on plants getting into soil or near by the plants.

Efficient use of lands minimizing waste:

As noted above, in this process land is conserved. The recycling takes a small foot print, requires no windrow processing, and can be done by decentralizing waste processing centers.

Biologically active soils with healthy plants produce more food.

Soil fertility:

Soil fertility is a measure of the ability of soil to support healthy plants. It is well known that soils with a vibrant diverse population of micro flora, fungi, spring tails, spirochetes, earth worms etc. (the diverse soil food web) are fertile and support plants well.

The quality of soil and improved diverse populations are observed when fermented green waste is brought back to soil. Many growers have experience with rapid improvements in soils that had been previously observed as poorly performing.

Routinely growers report on soils devoid of earthworms before being treated with fermented end products recovering quickly. They observe improved tilth and earthworm population recovery after treatments are in place.

Summary:

The goals of solid waste management are generally to minimize polluting air, soil and water in such a manner as to also minimize risks and hazards to operators and processors with the least amount of adverse impact on populations while conserving resources.

All evidence to date shows that Bokashi (acidic anaerobic fermenting) does this most efficiently and cost effectively with many beneficial outcomes.

It is also one of the few technologies that requires minimal energy and time to accomplish the task of recycling green waste.

Food waste, manure, or yard waste are all easily fermented.

No significant risk to humans has ever been identified using this technology. Fermented products used in agriculture are non-toxic to handlers, process operators, or populations in the vicinity where end products are applied in agriculture.

Recycling waste releases no significant gases into the atmosphere. Water is conserved and putting fermented products into soil reduces the demand for watering plants.

Both phosphate and nitrogen are far more avidly locked into soil (struvite precipitation) and bound up with clay particles minimizing runoff into waterways when the fermenting process is implemented.

Much is to be discovered and gained by promoting and supporting new technologies that bring these benefits to the front line where they can be properly evaluated against other competing technologies.

Large scale operations are essential if we are going to solve the many problems related to recycling green waste.